At Harper Collective, we transform ocean plastic and waste into beautiful, functional designs — redefining luxury. The future of conscious consumption starts here.

Our passion for creating functional and beautiful products from "trash" has led us to share our entire sourcing process with others, promoting full transparency in our operations.

Five years ago, we set out to create a luggage line made from sea plastic and post-consumer recycled plastic. Despite making numerous mistakes along the way, we persisted in our pursuit of this dream, designing our cases and logo and beginning the long process of bringing our vision to life.

Fortunately, we received incredible support from Phil, our project manager who brought 45 years of experience in luggage manufacturing to our team. His expertise was a game changer for us as we navigated the complexities of the technical category of luggage.

Throughout the years, we developed each part of our product from scratch, learning and growing with each step along the way. Our commitment to sustainability and innovation continues to drive us forward, as we strive to create products that are both functional and environmentally responsible.

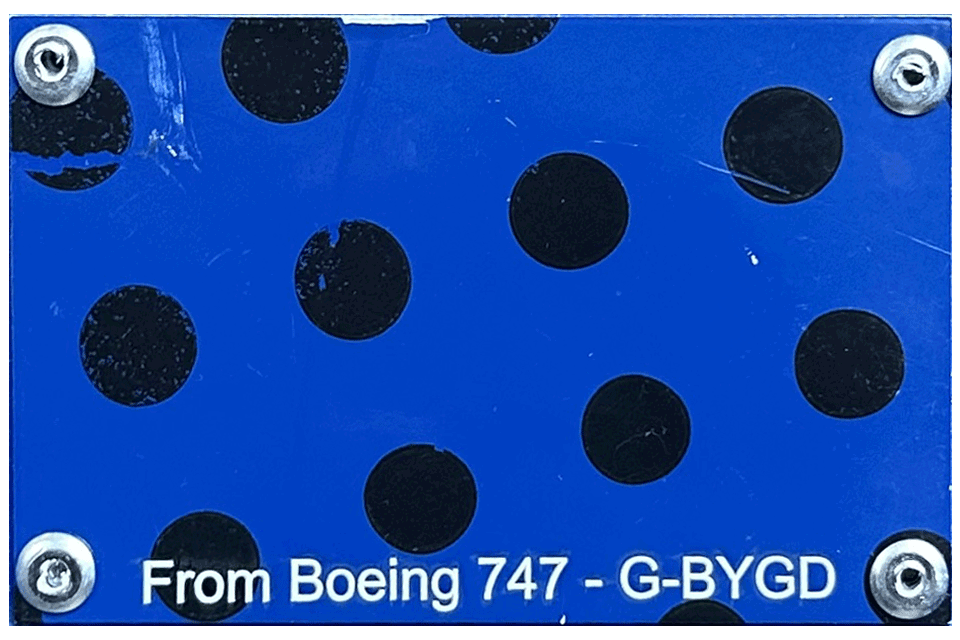

As part of our ongoing commitment to sustainability and craftsmanship, we’ve partnered with Plane Reclaimers UK, specialists in repurposing materials from decommissioned aircraft.

By sourcing our logo plates made from reclaimed aircraft body, we are able to transform these extraordinary, high-performance materials into stunning, one-of-a-kind art pieces. Each plate is a testament to our philosophy of reusing and upcycling, blending the history of aviation with contemporary design.

With our passion, we select the most beautiful sections of aircraft skin, restore them, and bring them to life as functional art. This collaboration continues our mission to source and celebrate the beauty of existing materials, turning them into lasting, meaningful objects.

This service is available inside the VAULT when you enter the Experience. The VAULT is our bespoke program.